How to select core shape for transformer and inductor design?

The core shape plays important role for optimum design of magnetic components used in electronic circuits. Here we shall discuss about available core shapes, the pros and cons of each type and guide you to choose the appropriate one. Though there are diversified core materials available and used in different applications, we shall disregard differences in core materials here and rather focus on core shapes.

A magnetic device such as inductor, transformer, common mode choke etc generate magnetic flux by driving electricity through a coil. The coil is nothing but a conductor arranged in compact repetitive windings like a spiral tube. While the magnetic flux lines rotate in circles around a straight conductor, they become concentrated towards the center of a spiral winding. When the core is placed inside this coil the flux lines run through the magnetic material in a least resistance path than the surrounding medium. By providing some particular shape to core the flux lines can be guided to flow through a well defined predictable path. The idea of magnetic core shape comes from it, to make a closed circuit for the flux to flow through primary and secondary coils or any other coil placed in the loop.

There are several standard magnetic core shapes available in the market. Let’s look into their properties and advantages in various applications.

Toroidal Core

Toroidal core has compact circular flux flow path. The fringing flux is zero as there is no air gap in core. The core loss of toroidal transformer is minimum among all core shapes. The heat generation is very low and efficiency is maximum with the given volume and surface area. The stray parasitic parameters are also at minimum. The primary to secondary flux binding is highest. No bobbin required for winding, which provides highest possible window utilization for transformer or inductor design. The winding of toroidal shape require special technique which may cause little higher production cost. It can have surface mounting or through hole mounting and can be placed at circuit board in many different orientations. Toroidal cores are very popular in audio and high power high frequency applications.

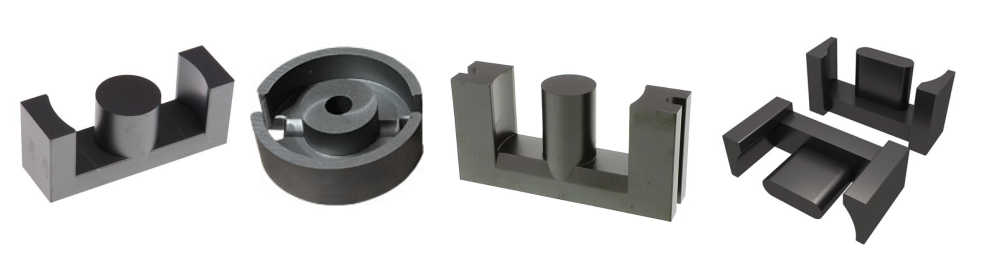

E Core

Below are the sub-types of E shapes

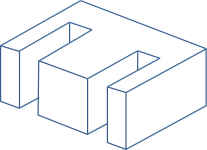

EE Core

EE Cores are most common in transformer design, they can be seen almost all types of applications. It is easy to manufacture and design with EE cores, therefore these are cheaper. The two E shaped parts of these cores insert into a plastic bobbin. Since there are junctions along the magnetic path fringing flux appears around the joint areas. There is the central column around which winding is placed where the flux gets generated. The flux lines flow along the two side limbs of EE shape. The core losses and heating exists in EE core transformer and inductors. There will be parasitic inductance and stray capacitance that need to be taken care during design and manufacturing. These parasitic elements if designed properly can be advantageous in resonance and filter circuits.

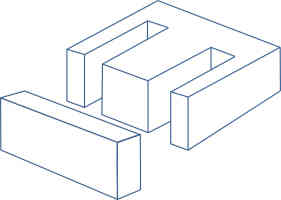

EI Core

EI cores are very similar to EE cores except that one of the E core is replaced with I shape. The E limbs are little bigger than EE core. Apart from ferrite type materials, laminated iron cores are manufactured in EI shape. The laminated E and I shaped iron plates are assembled as interleaved fashion. Laminated steel cores provide very high inductance values than ferrite counterparts. Laminated iron plate EI cores are suitable for low frequency 50/60 Hz power conversion applications. The high impedance at primary winding allows direct connection to 230/120 volt power line.

EPC Core

EPC core is suitable for low height horizontal surface mounting. This special shape require customized bobbin. The cost of transformers and inductors made of EPC core are on higher side. The core has uniform cross section. Similar to other E type cores gapped cores of different AL values are available in EPC shape. The heat dissipation characteristics are excellent. These cores are suitable for high frequency high power applications.

EFD Core

Similar to EPC core EFD core is also suitable for low profile surface mounting. The bobbin for this core comes in horizontal mounting. The cost of transformers and inductors made of EFD core are on higher side. The heat dissipation characteristics are excellent. These cores are suitable for small footprint high frequency high power applications.

ETD Core

ETD cores have cylindrical central limb within E shape that need specialized cylinder shaped bobbin. Winding and assembly process is fairly simple. Similar to E type cores ETD cores have poor electromagnetic shielding. Magnetic fields are generated close to the exposed winding. ETD core has uniform cross section and good heat dissipation. These cores can handle large power. These cores are suitable for EV charger, SMPS and other power regulation applications.

PQ Core

PQ cores find their application in power transformer and inductor devices. The center limb is in cylindrical shape. The electromagnetic shielding is better than ETD core. Heat dissipation is less effective but not too bad. The cost of core, winding and assembly are on higher side.

RM Core

RM cores have good self shielding from electromagnetic radiations. These cores are poor in heat dissipation. The cost of this core is on higher side. The winding window area are smaller relative to other shapes. The winding and assembly process is moderately complicated.

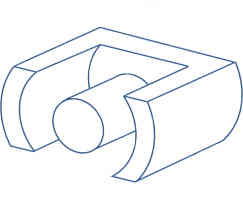

EP Core

EP cores have special cubical shape with cylindrical central limb. These cores are suitable for surface mounting. The winding window is smaller. The electromagnetic shielding is good but heat dissipation is poor. Winding and assembly cost and core cost are high. Since there is joint in between two core parts the fringing flux gets generated at the air gap.

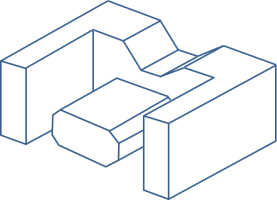

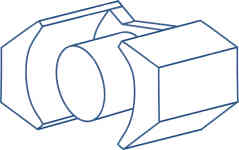

DS Core

The DS core has unique shape like distorted E with curved side limbs and cylindrical center limb. The bobbin and core come with higher price tag, winding and assembly process is straight forward. These cores can be used both in horizontal surface mounting or through hole vertical mounting configurations. The curved shape provides better electromagnetic shielding compared to EE core. Since the core has significant exposed area it can dissipate heat easily compared to other closed shapes.

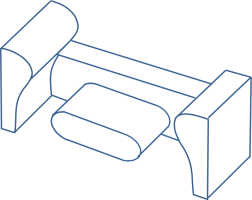

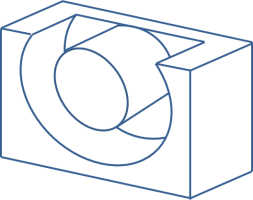

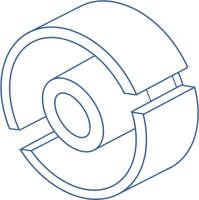

Pot/PM Core

Pot cores have excellent self shielding mechanism from electromagnetic radiations. These cores are expensive. The winding and assembly process is complicated. The winding window area is smaller. The heat dissipation is almost negligible as everything is confined within the shape. These cores are suitable for low loss design and low power high frequency applications. The mounting hole runs through the center of the core. The core cross section lacks uniformity. All these disadvantages are superseded by it’s electromagnetic radiation shielding feature. For critical EMI/EMC applications this core is de-facto choice for engineers.

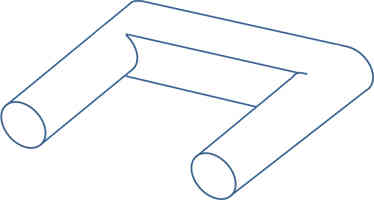

U Core

Below are the sub-types of U shapes

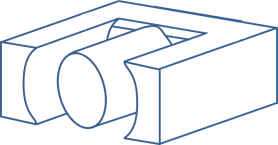

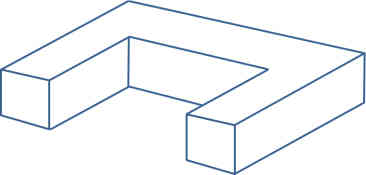

UU Core

U shaped core has two limbs. The winding can be placed on either of the limbs or both limbs. Placing coils on separate legs provide high voltage isolation among windings. These cores have versatile use in diversified applications. The winding window area is bigger compared to other shapes. Multiple UU cores can be stacked together for higher power applications. The core is cheaper and winding and assembly is simpler. The laminated version of this shape is also called C shape core. Many of high current inductors use laminated C cores for 50/60 Hz power line applications. These cores can also be used in split core current transformers.

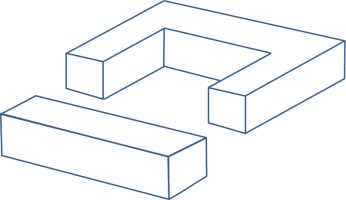

UI Core

UI core have similar properties as UU core, except it consists of I part and longer U part. The exposed winding generates electromagnetic radiation close to the device. Heat dissipation is excellent and therefore can be used in high power applications. The laminated UI cores can generate high inductance value.

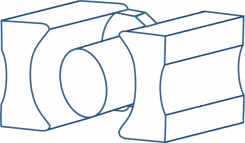

UUR Core

UUR core has rounded limbs. All other features of UU core applies here as well. These cores are easy to manufacture so they are relatively inexpensive. They are used in power transformers, noise filters, and output chokes in radio and TV equipment.

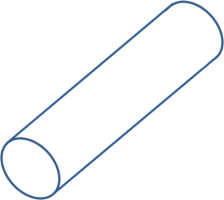

Rod/I Core

Rod cores are cheapest among all cores. The winding wire is wound around the rod. The winding is exposed and therefore electromagnetic fields are radiated close the device. The flux lines emanate from both end of the core as circular magnetic path not available in this shape. Transformers are not made with rod shapes as flux binding among multiple coils is poor. These cores are suitable for small value inductor devices. The winding wire thickness can be small or large depending on application. High current inductors can be manufactured easily using rod cores.

Drum Core

Drum cores are used in inductor devices. These cores come with two leads for through hole mounting. Without lead version of drum cores are also available for surface mounting. The electromagnetic shielding is very poor as winding is completely exposed. Cost of this core is very low. These cores are used in antenna, HF welding and other general purpose inductor applications.